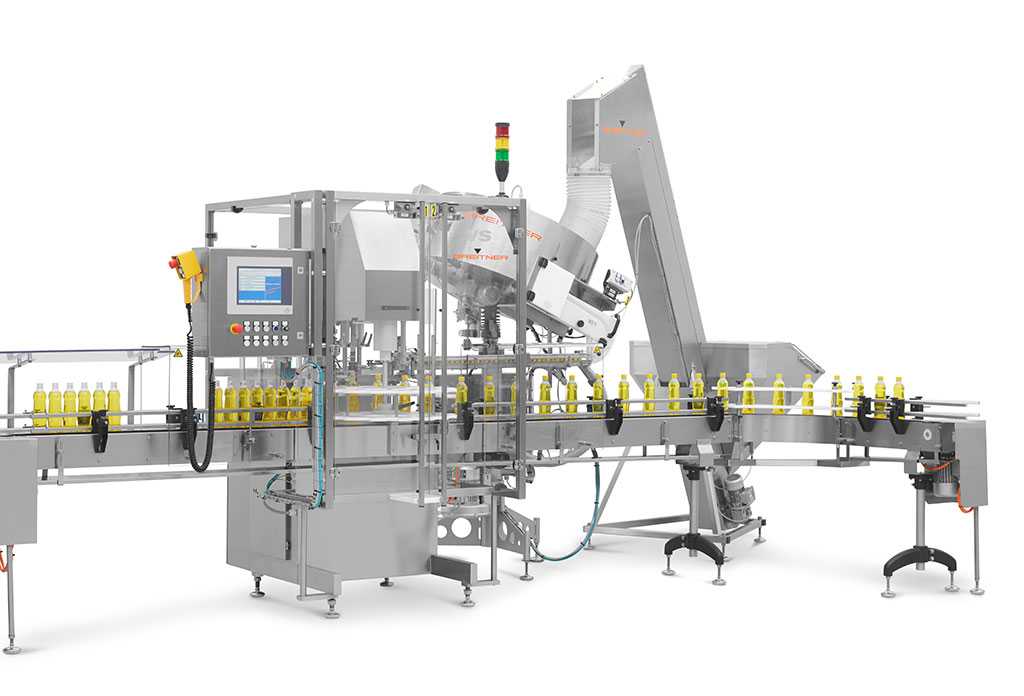

Intermittent rotary closing machine type VS/VC –

BREITNER Filling Machines

Intermittent rotary closing machine type VS/VC overview

The intermittent rotary closing machine type VS is the best-selling and flexible solution for screw-on and push-on closures.

The containers are transferred from the conveyor belt to a transport starwheel, which fixes them precisely under the screw spindle.

The screw spindle can optionally be equipped with a servo drive: This also allows, for example, aligned closures to be processed and the closing process to be monitored.

The VC machine variant also allows a stopper/dropper to be pressed into the bottle before screwing and then a measuring cup or dust cap to be fitted.

| Function: Pressing on / screwing on closures | Closure feed: reliably horizontal, transfer to the screw head via pick and place | ||

| Centring for the neck of the container | Easy & fast size change | ||

| EX protection (ATEX) (optional) | Type VC: In addition, it is possible to press in stoppers/droppers and attach dust caps/measuring cups. |

| Output rate: 60/min | Container diameter/width: up to 150 mm | ||

| Container height: up to 350 mm | Screwing torque up to 20 Nm | ||

| All adjustment positions with scale or counter | Format memory for 100 containers, incl. setting list for the adjustment positions | ||

| Graphical user interface with display of operating states | Password-protected user levels |

The intermittent rotary closing machine type VS is the best-selling and flexible solution for screw-on and push-on closures.

The containers are transferred from the conveyor belt to a transport starwheel, which fixes them precisely under the screw spindle.

The screw spindle can optionally be equipped with a servo drive: This also allows, for example, aligned closures to be processed and the closing process to be monitored.

The VC machine variant also allows a stopper/dropper to be pressed into the bottle before screwing and then a measuring cup or dust cap to be fitted.

| Function: Pressing on / screwing on closures | |

| Closure feed: reliably horizontal, transfer to the screw head via pick and place | |

| Centring for the neck of the container | |

| Easy & fast size change | |

| EX protection (ATEX) (optional) | |

| Type VC: In addition, it is possible to press in stoppers/droppers and attach dust caps/measuring cups. |

| Output rate: 60/min | |

| Container diameter/width: up to 150 mm | |

| Container height: up to 350 mm | |

| Screwing torque up to 20 Nm | |

| All adjustment positions with scale or counter | |

| Format memory for 100 containers, incl. setting list for the adjustment positions | |

| Graphical user interface with display of operating states | |

| Password-protected user levels |